Whether you are an OEM or an independent distributor buying on the open market, undetected substandard and counterfeit parts pose one of the biggest risks to your business. Counterfeit electronic component detection, via quality and authenticity inspections and tests, mitigates the extensive risks posed by substandard parts including excessive re-procurement costs, delays in time to market, and damage to your company’s reputation.

That’s where Advanced Component Testing comes in. We perform a series of counterfeit component detection tests to ensure all parts meet your quality standards, while identifying potentially counterfeit products in the process.

THE FIRST American Lab

Accredited to AS6171 Methods

See Cert Read PaperACT is on the Defense Logistics Agency’s Qualified Testing Suppliers List and is one of a few qualified labs for Lab Suitability for authenticity testing of electronic components. We also meet all aerospace AS6081 standards for detecting fraudulent/counterfeit electronic parts and can test low to moderate risk level parts to AS6171.

With approvals and accreditations demonstrating ACT meets the highest standards, our customers can be confident in the accuracy and reliability of the following component authenticity inspection processes:

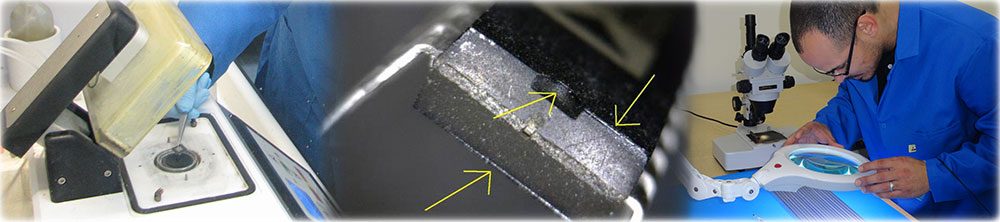

- External Visual InspectionACT component surface inspections, based on IDEA-1010/AS6081 standards, include visual inspection for surface defects and signs of counterfeiting including sanding, blacktopping, retinning and other remarking techniques, as well as comparison of part markings vs datasheet drawings.

- IC Decapsulation/DeliddingA chemical etching technique for opening IC plastic packages to expose their internal components and reveal die topography and size, manufacturer markings, copyright date, part number, and bond wires. Although physically destructive, the process leaves intact the die, bond pads and wire bonds.

- Lead Condition InspectionA visual inspection of all leads for scratches, gloss, color and texture, and evidence of contamination.

- Material Analysis/Device Composition via XRFX-ray fluorescence spectroscopy to determine elemental composition and identify specific trace elements.

- Physical Dimension InspectionAn examination of the physical measurements of each component for proper size, thickness and dimensions as compared to those stated on the OCM datasheets.

- RoHS Compliance/MIL Lead ComplianceVia XRF analysis, ACT performs nondestructive detection of hazardous substances, including lead to ensure RoHS lead-free compliance as well as existence of lead for adherence to military lead guidelines. ACT checks findings against data sheets.

- Marking Permanency InspectionSubjecting a device to a solvent to verify whether or not the ink markings on the device remain legible, as applied during the original manufacturing process.

- X-Ray InspectionA potentially destructive semiconductor failure analysis technique to examine internal construction to verify lead-frame geometry, die sizes, wire bond diagram integrity, and voids and cracks.

- Blacktopping InspectionChecking for signs that a component has been resurfaced or blacktopped post original manufacture via resistance to three solvents.

- Visual Analysis via SEMA Scanning Electron Microscope is used as part of a destructive physical analysis to verify aspects such as surface texture and metallization coverage.

- Resistance to SolventsA destructive test that consists of immersing devices into solvents, removing them and brushing the surface, repeating the process twice, drying, and inspecting for damage and possible adulteration. Multiple solvents used to test for surface alteration via blacktopping.

- BGA InspectionOptical and 3D X-ray inspection of solder balls for wetting, missing balls, shorted balls, shape, positional regularity, and patina. Substrate inspection for plating and scratches and FOD.

- Heated Solvent TestingACT immerses device into Dynasolve 750 or IM2P heated to their flashpoints to reveal potential evidence of tampering with part markings.

- Electrical Curve TracingEngineering review of the curve trace to check for PN junctions, shorts and open circuits—and matching findings against manufacturer’s data sheet.

- Mechanical Scrape TestA destructive test using an Exacto knife at a 45° angle to scrape the device surface in attempt to chip off layer of blacktopping.

- Die Verification via OCM Die DatabaseDuring internal visual inspections in conjunction with decapsulation/delidding, ACT may compare the die to our extensive proprietary OCM die database.

ACT provides a detailed final report that includes sampling data, color photos and a parts history analysis for all component authenticity inspection and testing.

Learn more about ACT: Electrical Testing Material Analysis Other Services AS6171

Related downloads: Quality/Authenticity Inspection Services